Some things You Might Not Know about Ratchet Straps

Ratchet straps are very familiar to flatbed truck drivers who use them to tie down everything from steel coil to landscaping products. You might even make the case that ratchet straps are among the most important cargo control tools a trucker can have on board. But there is a lot to know about these straps, how they are made, how they are rated, and so on.

Post date: 09-11-2017

6,207 view(s)

Interesting Things You Might Not Know about Ratchet Straps

Ratchet straps are very familiar to flatbed truck drivers who use them to tie down everything from steel coil to landscaping products. You might even make the case that ratchet straps are among the most important cargo control tools a trucker can have on board. But there is a lot to know about these straps, how they are made, how they are rated, and so on.

As a leading provider of cargo control supplies for truck drivers, we thought it might be interesting to help our customers test their knowledge of ratchet straps. Below is a selection of interesting things you may or may not know about these incredibly useful tools.

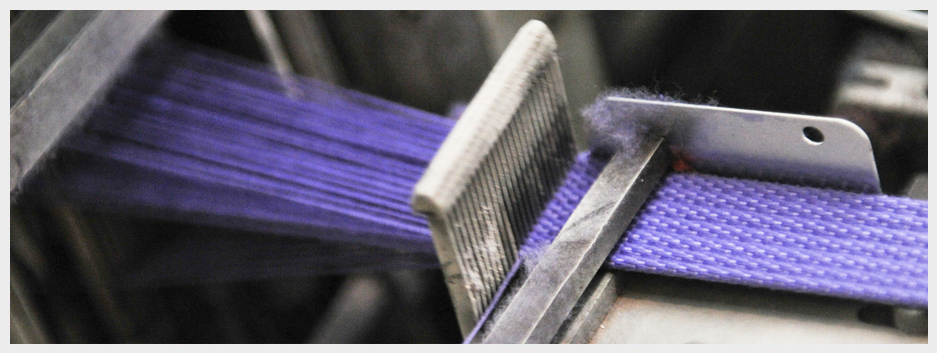

The Differences in Webbing Material

The polyester material from which ratchet straps are made is known in the industry as webbing. If you are even remotely observational, you have probably noticed that the webbing of a ratchet strap is fairly similar to the webbing used to make seat belts. You may have even noticed that webbing material is used in the manufacture of tarps, tents, backpacks, etc. But did you know that not all webbing is equal in terms of strength?

Polyester seat belt webbing is nearly identical to polyester ratchet strap webbing in terms of the material used. The main difference between the two is the strength of the webbing. Seat belt webbing is considerably thinner than its ratchet strap counterpart, and its tensile strength is much lower as well. Remember that a seat belt only has to stop a few hundred pounds, at most, moving in a single direction. Ratchet straps have to hold thousands of pounds in place by preventing cargo from moving in multiple directions.

Webbing’s Environmental Resilience

Webbing is the material of choice for all sorts of things because of its resilience. It holds up very well to an extensive list environmental conditions that would damage other materials. For example, it resists mildew and mold because it also resists moisture. Webbing does not shrink, it stands up to direct sunlight, and it is not affected by a number of acids found in industrial environments.

Not All Webbing Is Polyester

While polyester is one of the more common materials for making webbing fabric, it is not the only material. Webbing can be made of polypropylene, nylon, and even high-strength materials like Kevlar and Dyneema. Each of these materials has specific properties manufacturers are looking for when they create new webbing products.

Polyester is usually sufficient for typical cargo control applications within the flatbed trucking industry. But where extremely high tensile strength ratings are required, truckers might choose a more expensive product.

Webbing Construction Methods

Finally, the webbing material used to make ratchet straps can be constructed based on one of two weaves. The first is the solid weave. Solid weave is not the preferred process for ratchet straps because it is not as strong as the other process, known as tubular weave.

A webbing material constructed with the tubular weave utilizes flattened tubes of fibers instead of individual fibers in the weave. Using flattened tubes provides extra strength and shock absorption. Tubular weave webbing material is a bit more expensive, but you do get what you pay for when it comes to ratchet straps.

Yes, the trusted ratchet strap is one of the more important tools that flatbed truckers keep in their toolboxes. Ratchet straps are one of the keys to successful cargo control that is still efficient at the same time. Without ratchet straps, truckers would be left to secure their cargo with chains, ropes, and inadequate bungee straps.

PROVINA COMPANY LIMITED

Address: No. 243/4 Huynh Van Luy St, Phu Loi ward, Ho Chi Minh city, Vietnam.

Tel: (84) 274 6543 128

Hotline: (84) 901 548 578

Email: support@provina.vn / thanh@provina.vn

-------------------------------------------------------------------------------------------------------------------------------

Send your comment